What is a Combi Boiler?

- A wall hung boiler is a type of system that can provide hot water on demand, rather than storing it in a tank or cylinder. It is called a combi boiler because it is a single unit that serves two ‘combined’ functions: heating and hot water for the average household.They are easy to install, simple to use and, economical to run.

- Cost effectiveness, high operational efficiency, ease of installation, and compact size are some of the key factors driving the global combi boiler industry. These systems provide reduced operating cost and improved efficiency.

- Conventional boilers are being replaced by the combi boilers due to the introduction of several regulatory norms resulting in increased demand for energy efficient space and water heating systems.

Combi Boiler Market

As the Combi Boiler provides both functions in a single compact unit, its demand is growing in the region, which, in turn, is estimated to boost the market growth. Moreover, the high urban population in developing countries is further forecasted to fuel the market growth. As per the World Bank data, 56.156% of the global population lived in urban settlements in 2020. The increasing urban population is foreseen to increase the demand for combi boilers.

Laser ISSE, with its contribution to the manufacture of Combi Boilers, supports the boiler industry’s continually growing urban demand of energy efficient heating system required in the regions where the urban population showed a significant increase.

With its low energy consumption and efficient laser welding systems, Laser ISSE not only offers sustainable quality products, but also responds to cost-effective and energy-efficient heating system demand.

What is Laser Welding?

- Laser welding is a state-of-art joining technology that works by using a focused beam of light to weld metals together. The beam provides a concentrated heat source, allowing for narrow, deep welds and high welding rates.

- When the beam interacts with the surface of the material, laser beam melts the materials to be joined along the joint.

- The melts flow into each other, and the solidified melt connects the materials permanently.

- This feature makes the laser welding ideal for applications where accuracy, cleanliness and permanence are critical to success.

With many different types of laser solutions available, laser welding can be performed in many different industries. Based on its expertise over the years, Laserisse offers solutions for the heating sector: Combi Boilers.

Conventional Assembly of Combi Boiler Side Panels / Metal housing

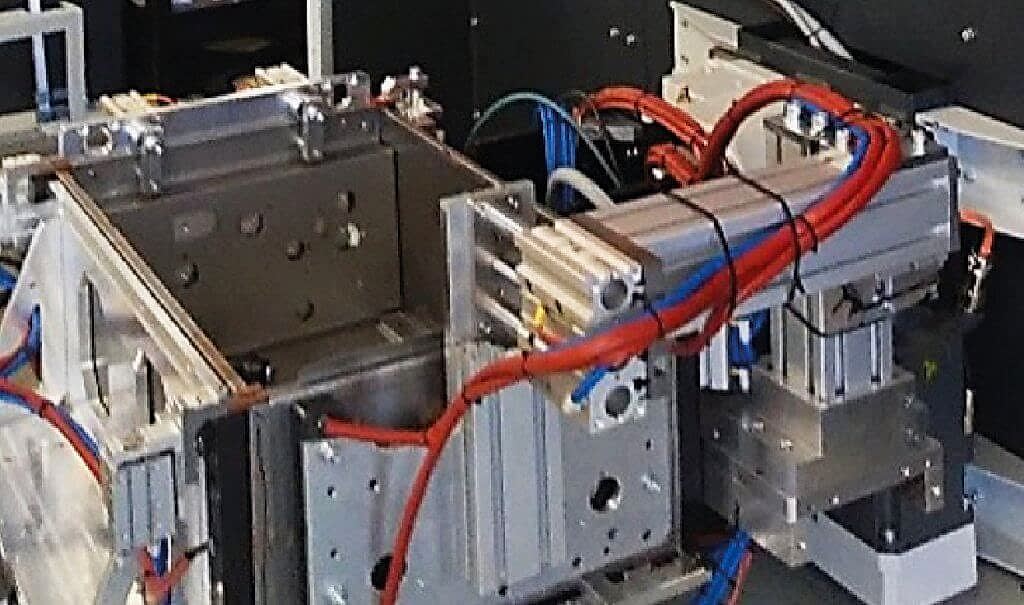

The Combi Boiler housing structure, which is made of Siliceous Metal Sheets with a range of thicknesses from 0.8mm-2.5mm, consists of left, rear, right, top, and bottom panels which are linked to each other by multiple bolts. After more than 50 bolts are tightened, connection surfaces are subject to a sealing process. The challenge is to maintain repeatable quality in production and improve the cycle time.

Customer Requirements

- Modification of the assembly line

- Eliminate sealing and tox process

- Optimum leaking test results

- Ability to weld variety of Combi models with one welding system

- Increasing the number of Combi models to be welded

- Fixture design and manufacturing

- Laser safety system in accordance with relevant regulations

Current cycle time / 7-12min – Target cycle time / <2min

The challenge is to determine the right laser source power and other components in order to achieve the target cycle time, since overlap welding of materials of different thicknesses requires experience. Another challenge is to design fixtures for each Combi models, which are highly affected by the contact/joint quality of the sheets.

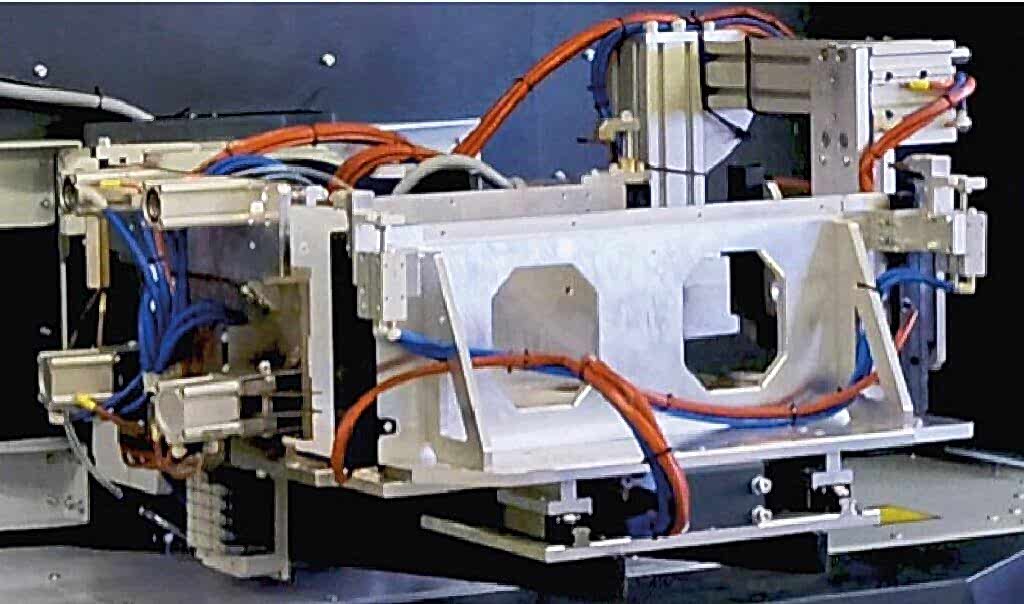

Laser ISSE’s Laser Welding Cell offers significant advantages over conventional assembly methods. The ability to load the boiler panels into the relevant fixtures easily and to operate the system in specific time frame makes laser welding the most ideal solution in terms of errorless and sustainable production.

Customer Benefits

Cycle Time

Before / 7-12min After / 72seconds

- Less manpower, less human error

- Less error, zero quality escapes

- High Efficiency

- Cost saving

- Quick return on investment (ROI)

- Significant increase in production volume per shift (Cycle time:72 seconds)

Main Technical Specification

- Class 1 laser safe enclosure with laser protection window and interlock switches

- Trumpf Laser Source for unprecedented welding speed

- Laserisse Welding Head

- KUKA Robot (Right payload and ideal reach)

- Coaxial Camera System + Monitor

- Customized Air knife

- Assist Gas Nozzle

- Rotary indexing table

- Reducer for tilting and rotating of fixtures

- Positioners ( 2 Qty)

- Fume Extraction Unit

- Water cooling system (Chiller)

- Siemens PLC

- Profinet communication protocol

- Customized HMI screen

- Internal HD CCTV Camera, Monitor

- Safety relays and interlocks

- Automatic Sliding Loading – Unloading Doors

- Led Warning Signs, Lighting

- Active Safety Protective Window

- Safety Laser Scanner

- Safety Fence

- FDA approved, CE certificated

- Complies with IEC 60825 laser safety standards